SE32

with 13E1, CFB, 2012 version.

Schematic 1, SE32, April 2012 version......

The above Sheet 1 Mono Amp has similar operation to earlier SE32 from 2008.

The differences are :-

1. +750Vdc rail and 25k RLa for dc to EL34 is replaced with 60H

Choke + 5k resistance

from B+ rail = +509V. EL34 Iadc increased from 16mA to 24mA.

2. EL34 THD reduced due to high RLa ohms and to more linear

working point.

3. EL34 Rk has been fully bypassed, to lower the effective Rout of

the stage, thus improving

micro-dynamics at higher F. Gain is slightly increased.

4. The 68k RLa for dc to 6SL7 is replaced with CCS using 1 x

MJE350, thus much increasing

the Ia and anode load ohms to increase gain from 48 to 64, while

much reducing THD.

5. 13E1 cathode R&C bypass network and CFB OPT winding is

changed.

6. Eg2 increased from 170Vdc to 200Vdc. Active automatic bias

voltage adjustment is applied to

13E1 grid to allow for variation in samples of tubes selected for

use and for tube aging and variations

in static grid current causing grid bias change and elevated Ia.

7. Many other minor changes and tidying up of circuitry.

8. The open loop voltage gain of the whole amp is increased by a

total of about +4.5dB.

The amount of global NFB has been kept the same at about 9dB by

means of changing the GNFB

resistance divider to reduce ß, ie, the fraction of output fed

back to V1 cathode.

The 2008 amp needed 0.88Vrms input for clipping with 5 ohm load,

but now only 0.57Vrms input is

needed so that preamps are not needed and signals from a CD source

may fed directly to the amp via

a 20k log pot mounted in a metal box with source selector switch,

in what is also known as a "passive

preamp", ( which is misleading, because nothing is amplified or

passed through any active device within

such a box. )

9. A fraction of the EL34 cathode bias voltage Ek at point Z is

taken to the protection circuit in case of

an EL34 having bias failure.

10. The 13E1 cathode biasing RC network has been arranged so

R&C network is grounded with

local CFB winding on OPT now between cathode and R&C network.

11. A fraction of the Ek is taken from Point Y to the active auto

biasing and protection circuit input

points shown on SHEET 2 PSU. The variable bias voltage for 13E1

grid from BC327 on SHEET 2

is applied at point X.

12. C16 is added to bootstrap the bias Rg R22, 47k. This

resistance then effectively becomes a much

higher value of ohms at signal F of 280k, so its loading effect on

EL34 becomes negligible.

This reduced the 2H of EL34 enough to give a welcome reduction of

overall 2H at high speaker load

values where 2H of the EL34 adds to the 2H of the 13E1, so that 2H

cancelling does not occur.

The effect on 2H of bootstrapping or not bootstrapping R22 was

measured. The bootstrapping

gave better overall results than not bootstrapping so it has been

retained. The increase in screen

supply voltage gave slightly less THD with low value loads, but

the Rk at 13E1 needed to be

increased from 185r to 232r to get a slightly higher Ek so that

the centre value grid biasing voltage

remains at 0V with Ia at 150mAdc. There is a slight reduction in

maximum PO but the 13E1 should last

longer and be less likely to overheat. Using a CCS with a

transistor to replace R30,R31 Rk was

considered but thought to be unnecessary over-engineering.

Schematic 2, SE32 PSU, April 2012 version......

The above Fig 4 PSU sheet 2 schematic needs little explanation for

the basic rail voltages supplied by

the main large power transformer.

There is a second small auxiliary 5VA power trans shown which

powers the Bias+Protect schematic.

There are two inputs to the circuit from resistance dividers in

the cathode R&C biasing networks of

EL34 and 13E1. The active protection is based on using a faction

of Ek of EL34 or 13E1 to turn on a

sensitive gate SCR, C106D, if too much Idc flows between cathodes

and 0V. The large mains transformer

has its mains primary winding switched open with a relay operated

by the SCR. The "on" blue LED goes

out and red "fault" LED turns on. Owners can try to reset the amp

by just turning off, waiting 2 seconds,

then turning back on.

But if an underlying problem remains present, the amp will just

turn off again.

Over many years I have discovered how much damage has been stopped

in many amps where tubes

have failed or shorted speaker leads or faulty speakers have been

used.

The new addition in this bias+protect schematic is the use of Q1,

a pnp BC327 transistor which

constantly controls the Idc in 13E1 in addition to the R&C

cathode biasing network.

The Y input from 13E1 R&C bypass network is taken from join

between R30 & R31 on amp sheet 1

and applied to a base of Q1, BC327, through a base current

limiting R of 470 ohms.

This voltage normally about +8.2Vdc. The BC327 emitter has 680

ohms to a fixed +12Vdc.

The BC327 collector has 4k1 taken to a -17Vdc supply rail.

The bias current for the BC327 is 5mAdc.

The 13E1 grid bias voltage is derived from the collector voltage

of Q1, and sent out via path X to a

33k then to bias resistance of 47k The Q1 collector load R1, 4k1

is bypassed with C1 4u7, thus the

33k and 4u7 form a filter preventing high level audio signals at

13E1 cathode appearing at Q1 collector.

There is about 0.022Vac ripple voltage at -17Vdc rail and at Q1

collector, and this is prevented from

appearing at the 13E1 grid because join of 33k and 47k is bypassed

with the 2uF bootstrapping C16 on

sheet 1.

In effect, the whole arrangement shown prevents unwanted signal

flows in 2 directions. The gain of Q1

is highest at very low F, and only about 5.5. If the Idc flow from

13E1 increases say 10mA, then Vdc

at point Y will rise by +0.5Vdc. This will appear at Q1 base and

be amplified x 5.5 to cause a correction

voltage of -2.75Vdc to be applied from point X to the grid. If the

tube transconductance = 20mA/V

then the reduction of tube current would be -55mAdc. In fact, the

Q1 acts to regulate the Ek Vdc appearing

at 13E1 cathode, and thus keep Ek more constant than if a much

larger value of Rk was used, or if a an

active cathode current sink were used.

For example, I tried a couple of CV6045 of unknown brand and with

the ordinary cathode R&C network

used for the 13E1 made by ITT. The Ia went up to 180mA, and Pda

went to 83W, which is TOO MUCH.

With the active Q1 bias regulator, Ia remained less than 160mA,

with a few -Vdc applied to grid, and Ek

remained close to where it should be.

In other words, the Q1 circuit acts to provide DC feedback. The

time constants chosen for R and C parts

ensure the bias trimming circuit is not unstable at some low F

which can so easily be a very real problem

if the time constants are ill-chosen, or the the gain of the

transistor is too high to try to get absolutely perfect

bias control.

The arrangement for 13E1 cathode biasing and screen supply has all

the current supplied to the screen and

through the shunt regulating zener diodes. So if any variations to

Ig2 occur, then Ek will not change as a result.

It the screen was ever to short circuit to cathode, or more

likely, the bypass caps between screens and

cathode short circuit, then maximum current through screen supply

resistance R32, 23k5, sheet 1,

is 21mA, only 10mA more than normal. The tube would not work if

screen supply voltage reduces to the

same as Ek at cathode.

Without the active grid biasing adjustment, the bias current of

13E1 is completely dependent on the R&C

biasing network. This R&C bias network does not have a very

high amount of resistance, so some help to

avoid problems with biasing from one lone easy-to-get transistor

is very welcome, and in fact, forgivable,

because try hard as you wish, but its presence is utterly

inaudible, while helping the music to be better

sounding, just for you. The other feature of my new biasing

circuit has the biasing R&C network subject

to all the screen current plus the current through the zener diode

shunt regulators. At idle, about 12mA

flows from B+ to screen and zener diodes.

During normal operation, the total of 12mA does not vary even if

screen current input were to vary

between a normal 4mAdc at idle to 12mA at high levels. The shunt

regulators tend to keep Ek more

constant than if they were not used, or if zener diode current was

not included in in the flow through

the R&C biasing network as shown for the 2008 schematic.

The other source of class A tube amp bias problems can be due to

mains voltage variations.

Triode and UL amps are most prone to enduring higher than wanted

Ia with abnormally high mains Vac.

If an amp has been designed badly with mains primary meant for

only 110Vac to suit USA and 220Vac

for everywhere else, then just 2 x 110Vac windings can be in

series or parallel to suit the national Vac.

But here in Oz, I have often measured 255Vrms and when used with

an amp with 220V transformer,

the heater voltages rise from the correct 6.3Vac to 7.3Vac, and

Vdc can rise from the intended +400Vdc

to +463Vdc, and if the Idc flow was a normal 70mA in an output

tube with a well regulated bias voltage

supply, then Ia might rise from 70mA to 85mA, and tube Pda rise

from 28W to 39W, and this can place

tubes very close to their Pda limit. With many hi-end and low-end

brand-name amps I have seen tubes

fail due to overheating when the amps are used here.

Therefore, it is WRONG to regulate grid bias voltage supplies

because if the mains voltage is too high,

then you want the bias to increase with mains voltage increase and

this tends to compensate the effect of

having a high mains voltage.

Alternatively, if the mains voltage is lower than normal, the grid

bias voltage may be less to allow more

Ia to flow. In my schematic above, the +/- 17Vdc rails are not

regulated, and if the mains voltage is high

then -17Vdc rail becomes more negative, and tends to reduce

excessive Ia. At dc operation, the Ra of

the 13E1 tube is very high, perhaps 10,000 ohms because the screen

is shunt regulated and kept at a

constant voltage above the cathode voltage. With 13E1 used in

triode or UL, Ra is less than 1,000r,

and a rise of 50Vdc in Ia would cause a rise in Ia of maybe 50mA

which could make Pda very excessive.

With my active biasing adjustment, and with shunt regulated Eg2,

there will be few problems with any

variations in mains voltages.

The 2 amps in which this bias scheme has now been employed were

brought to me a couple of months

ago for a service, the first since 2008. I advised my client that

more could be done to improve

performance, so the 2012 schematics were evolved.

The amps had been used very often, and the owner sometimes had

them running for days on end.

A colleague told me the rated tube life for 13E1 is around 2,500

hours. The first pair of 13E1 had lasted

from 1997 to about 2005, and this last pair from 2005 to now, and

from what I know, the hours of use

have much exceeded 2,500. All 4 tubes used since 1997 were ITT

brand. In the two last tubes, the

operation of both were flawless and without reverse grid current

or fading emission and both were able to

give a full 31W+ of power, and bias remained stable.

However, the gettering in one tube shows considerable browning and

aging, while in the other the

gettering has almost all become transparent but muddy brown, so

both these tubes will be replaced with

NOS with nice clean bright silver gettering. The result of all the

alterations should raise the sound quality

to be equal or superior to my SE35 amps with a quad of EL34 output

tubes.

Gettering wear indicates tube condition....

Image 2, May 2012.

Looks unused-----------------------------Looks a bit

worn--------------------------Looks worn out

On the left side of the picture, there is a NOS 13E1, never been

used.

The two other tubes were installed in around 2006, and they show

classic signs of gettering change

from the clean bright silvering on unused NOS tube.

The metallic content of the worn tube gettering has partially

combined with gas entering the tube through

join between base pins and glass and/or from slow release of gas

from within metal parts inside the tube.

Both the worn tubes remain capable of producing full power, but

only one now has begun to have a

slightly positive grid voltage relative to applied grid bias

voltage. The value of grid biasing resistance is

a very important design consideration, and I have seen some amps

such as Quad-II with bias R values

much too high at 680k. Hence KT66 in Quad-II with slight tube

aging may have very unbalanced Ia

because one tube has perhaps +5Vdc at its grid when it should be

less than 0.5V, which would be

possible if the Rg was 68k instead of 680k. I chose Rg at 47k for

13E1, and much lower than many

other makers might use, but it HOLDS the bias down. Reasons for

high value Rg are due to having

very week driver tubes such as EF86 in Quad-II with Ia less than

1mA, and to get the wanted gain the

load values much be kept high due to very low tube Gm.

In not a huge amount of time, the worn tubes with gettering nearly

all oxidized, tubes will develop

increasingly positive grids, and at some point the gas inside the

tube cannot be further kept low, and

the vacuum "hardness" is lost. Gas will increase, and tubes will

begin to conduct much more Idc than

usual and then overheat, as determined by Pda = ( Ea x Ia ) Watts

and they may melt down internally,

or cause glass to melt, or glass to crack, and perhaps cause

damage to PSU and/or OPT.

Sometimes internal grid wires will warp and anode will be shorted

to cathode and then high PSU

current is drawn and a mains or HT fuse will blow. But all too

often, amp damage occurs well before a

fuse blows. My active protection circuit will prevent such

pyrotechnic melt down by turning the amp

off safely and automatically.

The active bias adjustment circuit will try to bias the grid more

negatively as the Ik increases due to

a positive going Vdc, thus the tube life is extended maximally

even when tube failure is not far away.

The biasing circuit cannot keep old tubes working with enough Eg1

compensation, and eventually

the protect circuit will work unless an owner sensibly replaces

the tubes before they degrade so badly.

What you cannot see in the picture above is that the very good

looking unused 13E1 is completely

useless. When I tried it the screen current was about 12mA instead

of the correct 4mAdc for the

value of Eg2 with respect to Ek. Screen current is always a worry

with any multigrid tube, and of

course in every batch of NOS tubes bought so carefully from

someone@somewhere there will be

an occasional dud, and here is one.

But the tube caused no damage when tested in the SE32 because the

high Ig2 causes the shunt

regulated Eg2 to just sag down to a lower level so the tube

conducts less than normal Ia, and

nothing is damaged, although with only 60% of normal Ia, the power

output is much reduced and THD

becomes high at high music levels.

So nobody should ever assume a newly made or NOS tube is working

just fine after plugging one in.

Regular servicing is the answer, and maintaining a well paying

kind of respect for your local tube amp fixer-upperer.

Image 3, close up of nearly worn out 13E1 tube...

You can see how bad the worst of two worn tubes have become after

years of wonderful music.

There is a reflection of a window on the top left of the picture,

but very nearly all gettering

metal has been used up on the two sides of the tube. You can see

the round gettering rings

which were fitted when the tube was made, and it was from these

rings that the metallic

gettering was sprayed onto the glass internally under a vacuum

during manufacture.

NOTE, Gettering changes shown above can occur in many other tube

types, and one may

see where gettering is "nearly used up" and if the tubes have been

used for 5 years it

is very wise to replace them. And NO, I do not have shares in tube

making companies.

I suggest everyone Google "vacuum tube manufacture" to learn more

about how

tubes are made.

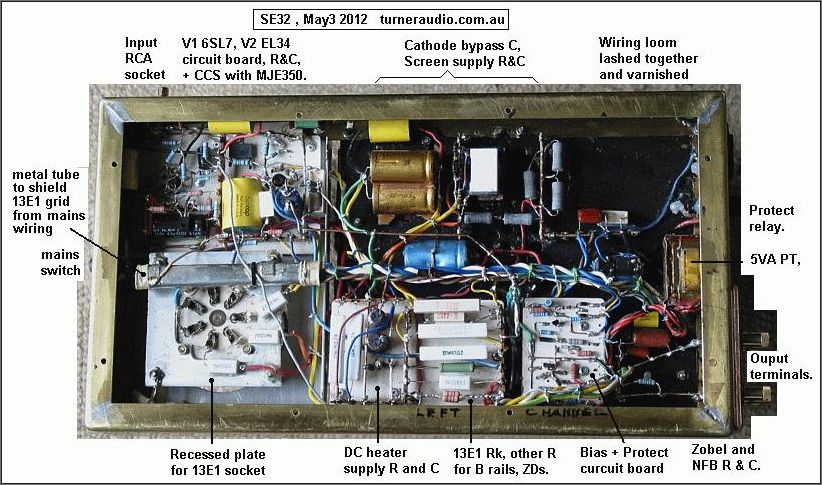

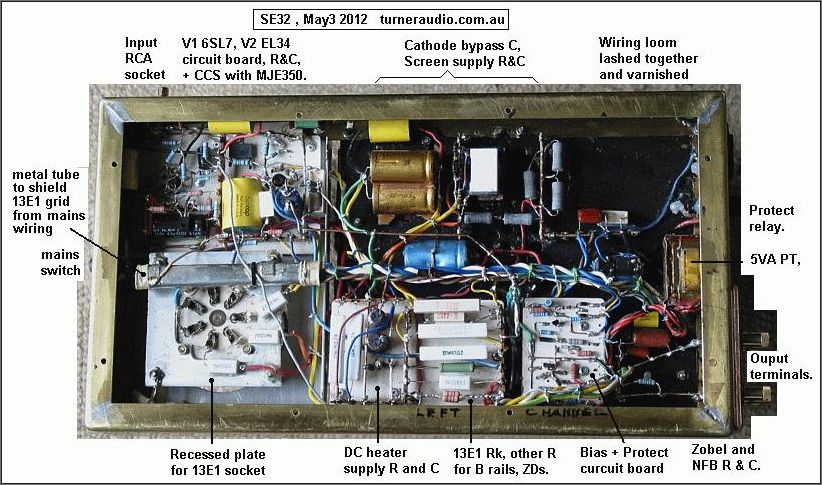

Some images for SE32, 2012.........

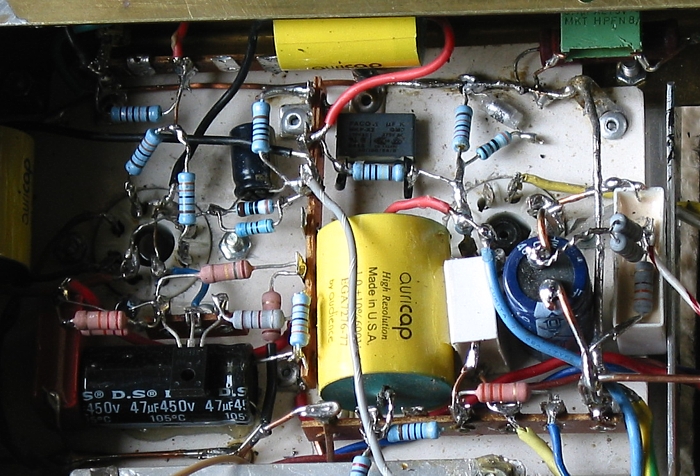

Image 4. Two SE32 monoblocs on bench, without covers.

Note capacitor enclosure bottom left. Easy access for setting for

OPT load match on

board on OPT for sec winding terminations.

Image 5. Two monoblocs on bench without covers.

This shows the layout of parts on top of chassis. Fully shielded

tube is 6SL7, with 2 reddish tube

dampers fitted by owner ( which don't do anything IMHO ). EL34 and

13E1 have dampers also

fitted. 13E1 has copper wire used to stop tube falling out of

socket which is possible due to

small socket size and weighty tube.

Iron wound components are OPT, left rear, Big mains PT far right,

anode choke for EL34

at left front, nearest, and 4H B+ filter choke between PT and

anode choke. Small 5VA

tranny for bias+protect circuit is under chassis. The six B+ 470uF

x 400V rated electrolytic caps

are mounted in a case behind the mains PT.

Image 6. Under chassis view.

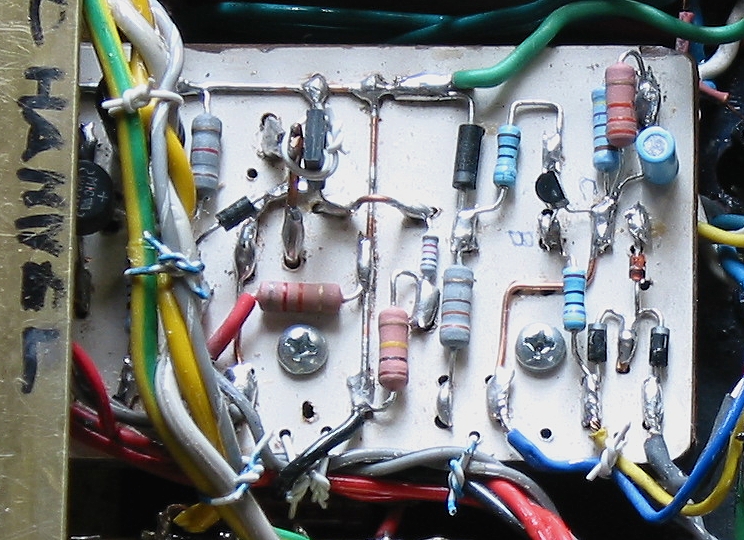

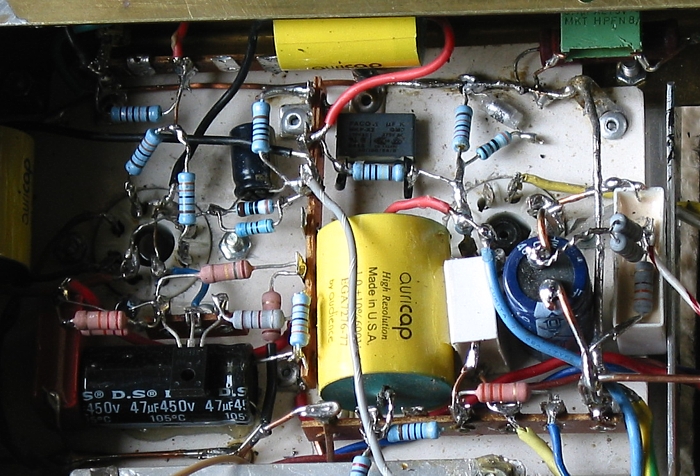

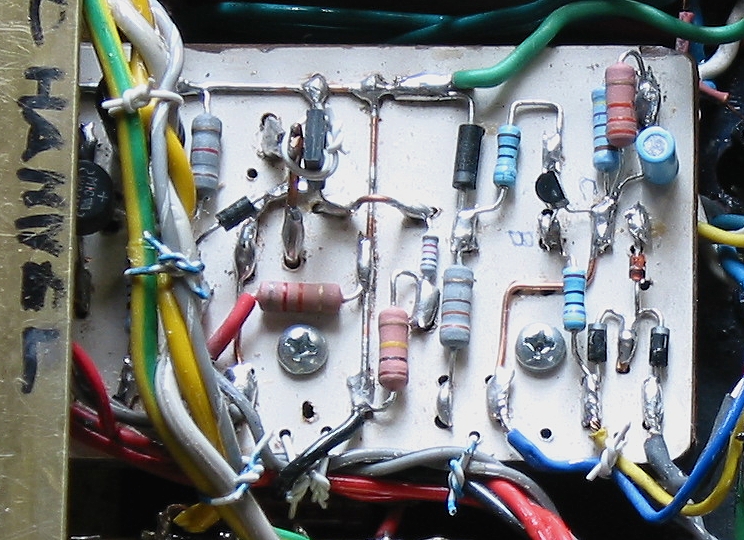

Image 7. Close up bias+protect board.

Image 8. Close up 6SL7 and EL34 board. Rather crammed.

Image 9. SE32, covers on.

Image 10, May 2012.

Mr Turner has more to say about SE32 amps.....

Happy soldering ! happy swearing ! happy stopping of the

amplifier smoking ! ,and then happy listening! :-)

To

SE32, 2008.

Power amps directory

Index page